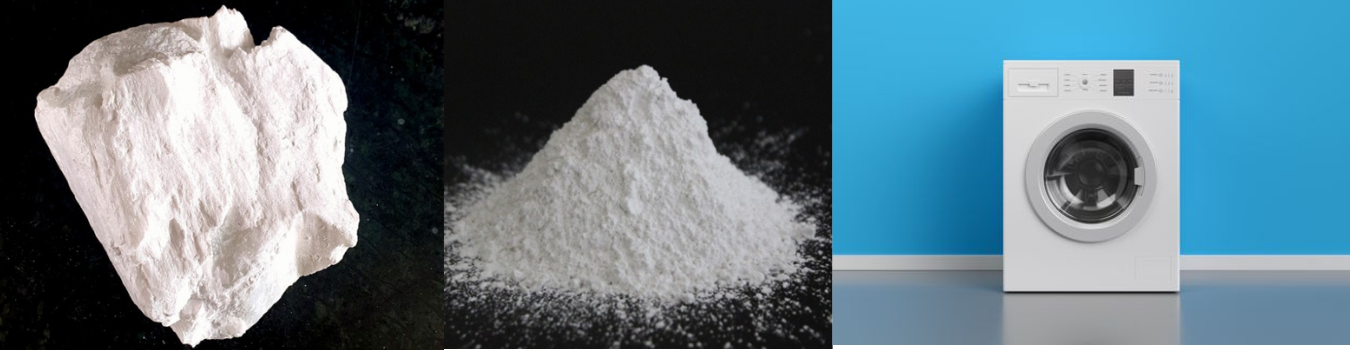

Talc compound manufacturers | Plastic grade talc

Talc plastic compound manufacturer is a soft mineral and easily micronize into fine particle sizes. Subsequently, these fine particles of Talc efficiently fill up inter-particular spaces within polymer compounds. This, in turn, increases the stiffness and impact strength of plastics and polymers.Adding talc to PP notably enhances its properties, including greater stiffness/rigidity; higher impact strength (particularly at sub-zero temperatures); better heat, creep and chemical resistance; and especially increased dimensional stability, even after molding.

Technical Specifications:

| CaO | 3.00%max |

| SiO2 | >63% |

| MgO | >32% |

| Application | Plastics |

| Type | Polyethylene Terephthalate (PETE),High Density Polyethylene(HDPE),Vinyl |

| Brightness | 98% |

The platy shape of talc particles can increase the flexibility of products without compromising on the scratch resistance and strength. Our transparent Talc Powder products are used in polypropylene, vinyl, polyethylene etc. It also increases the heat resistance provides excelled shine and transparency of these products and reduces shrinkage. Our talc's very low hardness produces less abrasion on equipment and the fine mesh makes sure that there is no blockage during extruding process.

Plastic Grade Talc: Enhancing Plastic Compounds with Precision

In the world of plastics, achieving the perfect balance of mechanical strength, processability, and surface finish is a constant endeavor. One key ingredient that has emerged as a game-changer is plastic talc. Talc, a naturally occurring mineral, possesses exceptional properties that enhance plastic compounds, making them more versatile and high-performing. Thus, let's delve into the significance of talc in plastic compounds, explore its role in manufacturing, and shine a spotlight on our company, Vasundhara Micro Mineral Infinite Pvt Ltd, one of the most reputed and trusted Talc Compound Manufacturers known for our expertise in producing top-quality talc compounds.What is Plastic Grade Talc?

It is a type of talc that has been processed and refined for its high purity and fineness. It is made up of magnesium, silicon, and oxygen and is naturally found in metamorphic rocks. When used in plastics, it provides a range of benefits, including improved stiffness, impact resistance, and dimensional stability.

Applications

With a huge range of supportive applications in the plastic industry it is commonly used in the production of polypropylene, polyethylene, PVC, and other thermoplastics. The addition of talc to plastics can improve their mechanical properties, reduce shrinkage and warpage, and enhance their heat resistance.

It is also used as a filler in plastic products such as automotive parts, electrical components, and household appliances. It can enhance the surface appearance and texture of plastic products, as well as reduce their weight and cost.Importance of Talc in Plastic Compounds

Enhancing Mechanical Properties

When it comes to plastic products, strength and durability are crucial. Plastic talc is known for its ability to enhance the mechanical properties of plastic compounds. By incorporating talc, we as a trusted Talc Plastic Compound Manufacturer significantly increase the stiffness, impact resistance, and heat resistance, thus creating plastics that can withstand demanding applications. Talc acts as a reinforcing filler, improving dimensional stability and reducing the risk of warpage or deformation.

Improving Processing Conditions

Plastics processing involves a myriad of techniques, such as extrusion, injection molding, and blow molding. Talc plays a vital role in optimizing these processes by improving flow properties and reducing friction. The lamellar structure of talc acts as a lubricant, facilitating smoother material flow and minimizing processing issues like melt fracture and die drool. This not only enhances productivity but also results in products with excellent surface quality.

Enhancing Surface Finish

Surface aesthetics are paramount in various industries, including automotive, consumer goods, and packaging. Talc, with its unique properties, can transform the surface finish of plastic products. By adding talc to plastic compounds, manufacturers can achieve a desirable matte or glossy appearance, eliminating the need for secondary processes like painting or coating. Talc also reduces surface defects such as sink marks and improves scratch and mar resistance, ensuring the longevity and visual appeals.

Reduced Cost

In some cases, using talc plastic compounds can be more cost-effective than using traditional plastic materials. Talc is a natural mineral that is abundant and readily available, making it a more affordable option for many manufacturers.

Vasundhara Micro Mineral Infinite Pvt Ltd: One Of The Leading Talc Compound Manufacturers

We are a leading Talc Plastic Compound Manufacturer, we are an Indian-based company with over three decades of experience in the talc industry. Here's what sets us apart:

Expertise in Talc Compound Manufacturing

We have a deep understanding of the properties and applications of talc and leverage this knowledge to develop customized solutions that meet the specific needs of our clients. We offer a wide range of Plastic grade talc compounds that are tailored to enhance mechanical properties, improve processing, and achieve desired surface finish.

Quality Standards and Certifications

We are committed to delivering products that meet or exceed international quality standards. Our company has earned several certifications, including ISO 9001:2015 and ISO 14001:2015, which attest to our commitment to quality, safety, and environmental responsibility.

Plastic grade talc compounds play a crucial role in enhancing the mechanical properties and surface finish of plastic products. As a Talc Plastic Compound Manufacturer we Manufacture these compounds with a precise and delicate process, starting from the selection and quality control of the talc to the mixing with other ingredients and quality assurance tests. Using talc plastic compounds offers numerous benefits such as improved mechanical properties, surface finish, reduced cost, and environmental sustainability. As the demand for high-performance plastic products continues to rise, the importance of talc plastic compounds in the manufacturing process will only increase.

Known for our promse to innovation and quality we use state-of-the-art technology and equipment to manufacture our products, ensuring consistent quality and performance. Our products are also environmentally friendly and comply with international standards. Offering a range of Talc plastic compounds that are tailored to meet the specific needs of different industries with an easy to use feature and excellent dispersion, we make them ideal for a wide range of applications. Thus, we are catagorised as one of the leading Talc Compound Manufacturers.